This table below can be used for fast calculation of steam pipes sch.

Steam pipe insulation thickness table.

Table 120 3 a pipe insulation thickness.

Includes 53 different calculations.

Table 10 2 1 compares the actual bore sizes of different sized pipes for different schedule numbers.

Heating pipes steam steam condensate and hot water.

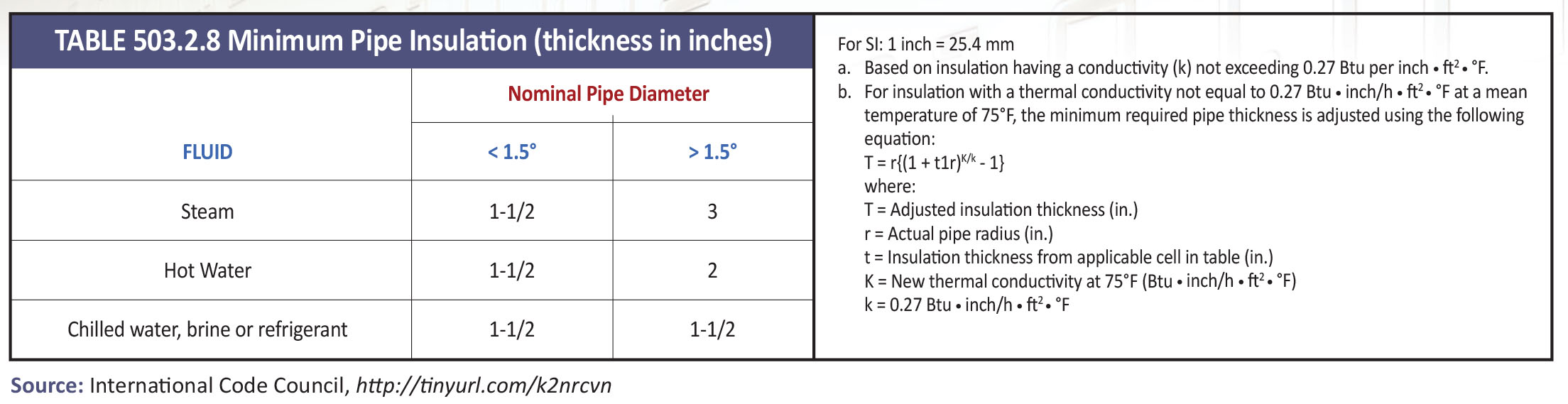

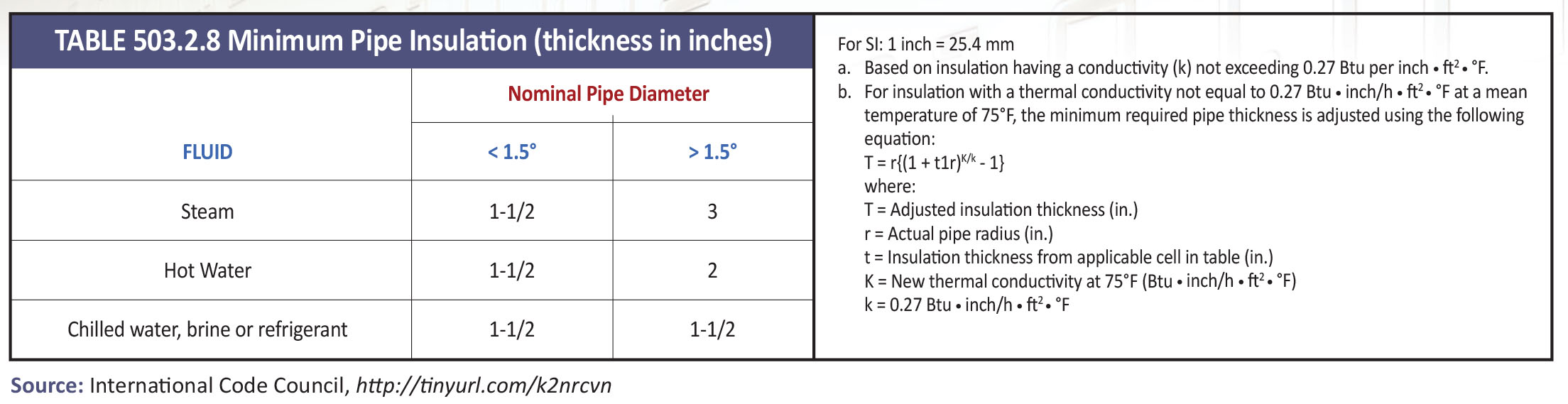

In each table minimum insulation thicknesses are referenced for both pipe size and for operating temperature.

All steam steam condensate and hot water lines.

Tables of schedule numbers can be obtained from bs 1600 which are used as a reference for the nominal pipe size and wall thickness in millimetres.

In general 80 ft sec is a recommended steam velocity.

Steam pipes low to high pressure condensate lines.

Fluid temperature range f conductivity range in btu inch per hour per square foot per f.

In the new standard these tables are also reproduced in metric units.

Equations displayed for easy reference.

This is by far one of our most popular commmerical uses of our fiberglass pipe insulation due to the large energy savings for building owners.

This calculation determines the ideal thickness of water piping insulation for efficiently and economically preventing a heat transfer from outside to inside and keeping the water transported within cool it does not determine the thickness of insulation designed to keep condensate or other fluids from losing heat.

T insulation thickness from table 120 3 a inches.

6 7 bs5422 table table referencepage no 6 minimum insulation thickness for chilled and cold water steel pipes to control condensation on a high emissivity outer surface 0 9 with an ambient temperature of 25 c and a relative humidity of 80.

Refrigerated chilled liquid pipes.

For full table with larger dimensions rotate the screen.

There are two sizes you need to cho ose when ordering the pipe size and the insulation thickness.

Sizing steam pipes in si units.

The insulation thickness is the wall thickness of the fiberglass which varies from 1 2 up to 3 thick.

The values are in figures 1 and 2 complete with the footnotes.

Choosing the correct size.

The minimum pipe insulation thicknesses are given in two tables 6 8 3a and 6 8 3b in the standard.